Injection molding is a common 21st-century manufacturing method.

Thermoplastics and thermosetting polymers are the two types of materials used. However similar processes use glass (blow-molding), metal (die-casting), and elastomers.

Injection molding manufactures a vast array of day to day objects from IoT enclosures, transportation parts to kitchenware.

Injection molding is widely used as it has the ability to produce complex geometries at fast rates with feasible costs.

Chapter 1

Injection Molding Fundamentals

Whether you’re new to injection molding or looking to brush up on the basics these resources will either help get you up to speed or act as a refresher.

You’ll learn when, how, and why injection molding was discovered and the injection molding fundamentals.

- What is Injection Molding? History and Process[VIDEO]

- A Simple Animation on How The Injection Molding Process Works

- Step By Step Images and Description On The Injection Molding Process Works

![]()

Chapter 2

Injection Molding Part Design Fundamentals

You’ll learn how to design parts for injection molding around a set of design parameters. Failing to adhere to these design guidelines will result in part defects and other problems.

- Basic Injection Molding Industrial Design Guide[PDF]

- Intermediate Injection Molding Industrial Design Guide

- Advanced Injection Molding Industrial Design Guide[PDF]

Chapter 3

Injection Molding Materials

The materials we choose to manufacture your product effects costs, product performance and customer satisfaction and many other variables.

This chapter will inform you on the common injection molding materials used and how to determine what materials to use for your product.

- Most Common Plastic Injection Molding Materials

- Selecting the right injection molding for your product

- Injection Molding Materials For Medical Devices

Chapter 4

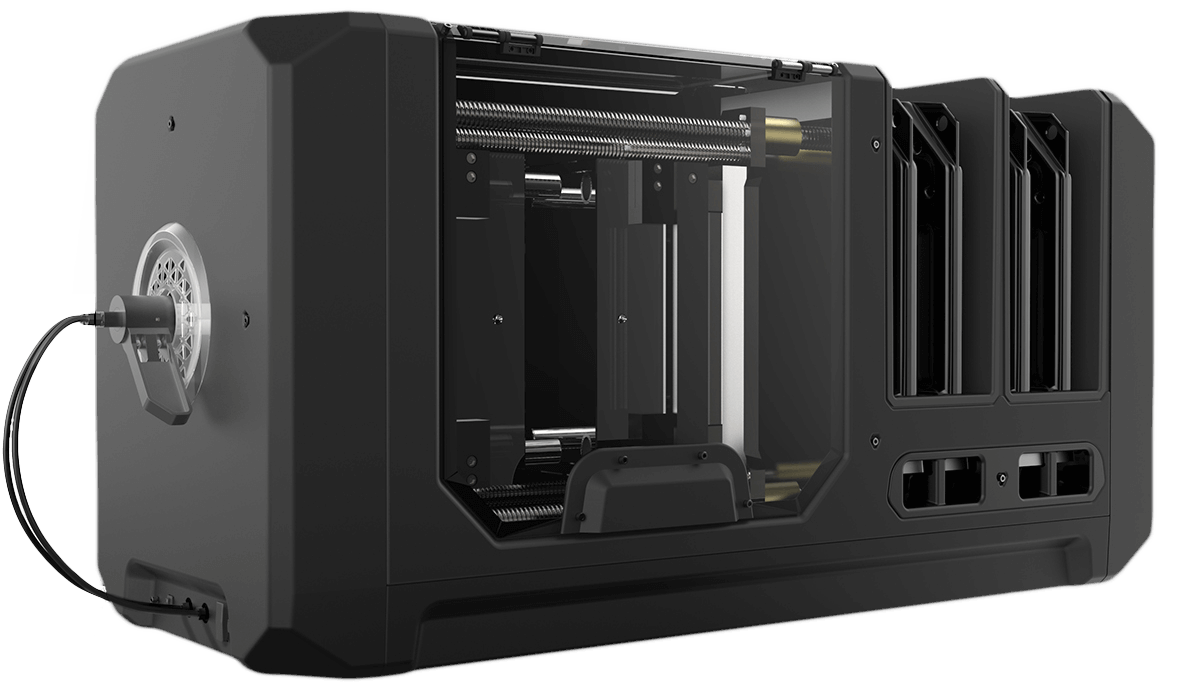

Injection Molding: Tooling Fundamentals

The injection molding process usually requires a custom mold specific for the part that you want to produce. The injection molding process usually requires a custom mold specific for the injection molded part that you want to produce. In this chapter you’ll learn what an injection mold tool is, what it does, how it works and how it’s designed from the article you intend to injection mold.

- What role does the molding tool play in the injection molding process?[VIDEO]

- Injection Molding Tooling Visuals & A Variable That Affects Cost[VIDEO]

Chapter 5

Alternatives To Injection Molding

One of the keys to having a successful Injection Moulded Part is to ensure the components is designed following strict guidelines. You’ll learn the fundamentals of how injection molding products should be designed without causing defects and problems.

- Superior, Low Cost Alternatives To Injection Molding

- Low Run, Low Cost Alternative To Injection Molding

- Vacuum Forming Versus Injection Molding

- Injection Molding Or CNC

- The Price Of 3d Printing Vs Injection Molding

Chapter 6

Incredible Injection Molding Case Studies

Real life injection molding case studies. You’ll learn insights on how businesses use injection molding to mass manufacture their product.

- Case Studies in Plastic Injection Molding

- Marco Beverage Coffee Reservoir Case Study

- Dipjar – Quick, Low Volume Injection Molding Case Study

Chapter 7

Other Great Injection Molding Resources

Other Great Injection Molding Resources that will benefit you.